From compression leggings and running shorts to yoga bras and training tops, now's your chance to get your favourite gear for less, whichever way you sweat.sometimes we make too much, and when we do, we don't want it to go to waste. Our pants fit like your favorite chinos.

Lululemon pullover Lululemon pullover size 2 lululemon

Lululemon pullover Lululemon pullover size 2 lululemon

In this guide, we’ll talk about the different fabrics, how they feel and what they are intended for.

Lululemon size guide socks. Here is a rough guide to how lulu’s sizes compare to us band size: Lululemon fabric guide + cheatsheet. Try some on so you can see how the bra feels on your body.

Normally we select bottom sizes based off our waist size. Shop leggings, pants, shorts, tank tops and sports bras from lululemon. 2 = 30 4 = 32 6 = 34 8 = 36 10 = 38 12 = 40.

Your recommended bra size is a starting point that should be used as a guide. 32 34 36 38 40 waist: Lululemon may record your ip address when you visit or use services or features on the sites.

Sidelineswap is where athletes buy and sell their gear. Most lululemon bras are not sized by band/cup and instead are marked with the same sizes as other items. Use the waist and hip measurements as a guide to pick the right size for you.

Check our size guide because great moves start with the perfect fit. White red pink black multi. Your recommended bra size is a starting point that should be used as a guide.

An ip address is a computer's numeric address, by which it can be located within a network. If you have already purchased an item by our brand, we recommend you select the same size as indicated on its label. Lululemon says its technical apparel is built for the body in motion.

Lululemon may record your ip address when you visit or use services or features on the sites. Bra support comes mostly from the band so it's important that it fits quite close to your ribcage. Normally we select bottom sizes based off our waist size.

Our pants fit like your favorite chinos. Use the waist and hip measurements as a guide to pick the right size for you. If you’re a 32 in the pants you have at home, you’ll likely be a 32 in our pants.

Our technical gear is designed to keep you comfortable and confident during all your sweaty pursuits. Socks (11) underwear (11) water bottles (5) scarves & gloves (1) yoga accessories (8). These socks have all the features you need to work, sweat, rest, and repeat—because you've got better things to do than remembering to pack an extra pair.

Try some on so you can see how the bra feels on your body. Lululemon may use your ip address for the purposes noted above, and also to help diagnose problems with lululemon’s server, or to administer the sites. If you're a 32 in the pants you have at home, you'll likely be a 32 in our pants.

Get ready to move in our sports socks. 1/27/2021 | lululemon fabric guide. Lululemon may record your ip address when you visit or use services or features on the sites.

Lululemon size xs s m l xl; Sizes are limited and run out quickly. The numbers above may vary from person to person, but they’re a good place to start!

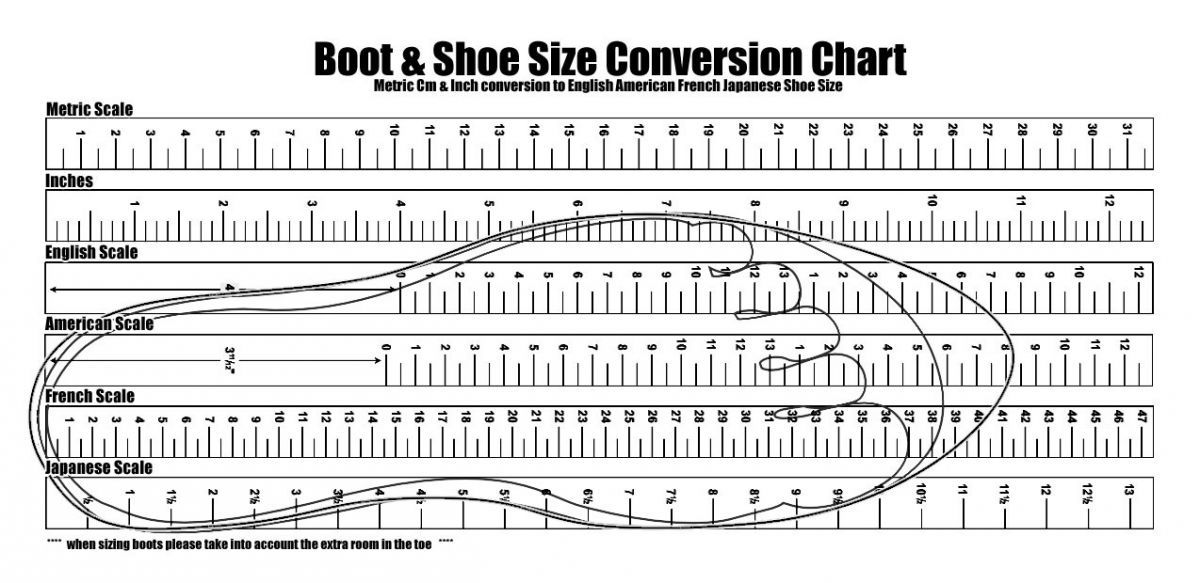

Every bra should fit snug—wearing it too loose won't provide you with the support you need. An ip address is a computer's numeric address, by which it can be located within a network. Size guide this is an approximate conversion table to help you find your size.

Bodies come in all shapes and sizes. Lululemon‘s many fabrics can leave you feeling perplexed about what to wear. Lululemon may use your ip address for the purposes noted above, and also to help diagnose problems with lululemon’s server, or to administer the sites.

Shop the bra guide at lululemon. Bodies come in all shapes and sizes. Get ready to move in our sports socks.

Lululemon will use information you provide to deliver you relevant information about our products and services, including offerings based on your preferences and purchase history. Shop apparel up to 70% off, or list for free in seconds. Women's we made too much.

Stocking women’s and men’s apparel and accessories you will find everything from tops, shorts, pants, skirts, swimsuits and dresses to socks and underwear, yoga mats, water bottles, jackets and hoodies. Closed saturday, sunday, and hong kong public holidays Instead, we give you the chance to upgrade your workout wear at the very best prices.

Lululemon may use your ip address for the purposes noted above, and also to help diagnose problems with lululemon’s server, or to administer the sites. Does lululemon offer plus sizing? Lululemon offers an inclusive size range from 0 to 20 in women’s apparel in their most popular styles.

Use this as a guide to help you find the lululemon fabric that you’ll feel great in. Lululemon extended plus size leggings review 2021. Every bra should fit snug—wearing it too loose won't provide you with the support you need.

14 loungewear deals that will knock your socks off. For added grip and extra warmth during yin class, pull on a cosy pair that’ll help keep you in place on the mat. A guide to buying your perfect bra online

An ip address is a computer's numeric address, by which it can be located within a network.